contact:Colin Han

email:sales@rfabrasive.com

phone:+8618553321311

address:Wenchang Lake Economic Development Zone, Zibo City, Shandong Province, China

Product Features:

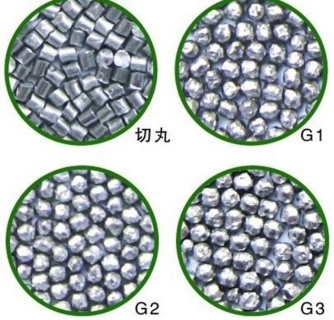

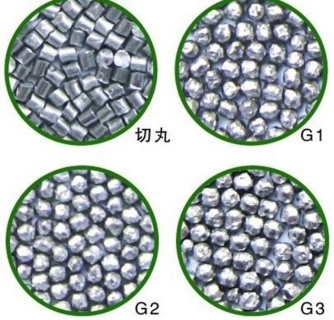

● High strength, long life, high toughnessSteel Cut Wire Shot

We offer three different hardness peening for high impact and shot peening. Ensures optimum shot peening performance.

HRC45-50 HRC50-55 HRC55-60

Steel Cut Wire Shot performance advantages:

●The selection of high quality alloy steel wire as raw material to ensure that it has excellent quality and higher mechanical properties

●Products are produced in strict accordance with German VDFI8001/2009 and American SAEJ441, AMS2431 standards, ensuring that all the produced cut wire shot is highly unified in size, hardness and density.

● Long life, impact resistance, toughness, not easy to break, the service life is 3-4 times that of steel shot

● No cracks, no pores, no breakage. Cycle times 4000-9600 times.

●Can maintain higher fatigue life under high hardness, stronger impact force,

Technical indicators:

Steel Cut Wire shot | Technique data | |

Chemicalcomposition | C | 0.70-0.86% |

Mn | 0.50-1.30% | |

Si | 0.15-1.30% | |

S | ≤0.04% | |

P | ≤0.04% | |

size | 0.4/0.5/0.6/0.8/1.0/1.2/1.5/1.8/2.0mm | |

Density | 7.8g/cm3 | |

Hardness | 40-45HRC/45~50HRC/55-60HRC | |

Ervin life | 6000-9600 times | |

Microstructure | Deformed pearlite | |

Steel cut wire shot purpose:

Mainly used in aerospace, national defense, military industry, nuclear industry, automobile gear, motorcycle, shipbuilding, transmission, spring, high-speed rail locomotive industry and other enhanced processing fields